1. The automatic production line of stretch film vacuum packaging machine is the only equipment on the market that can solve the automation of customer sausage packaging; it is customized according to customer product specifications and bagging requirements, which effectively reduces labor and labor intensity for customers. While improving production efficiency, it also greatly guarantees production hygiene and reduces direct contact between people and products;

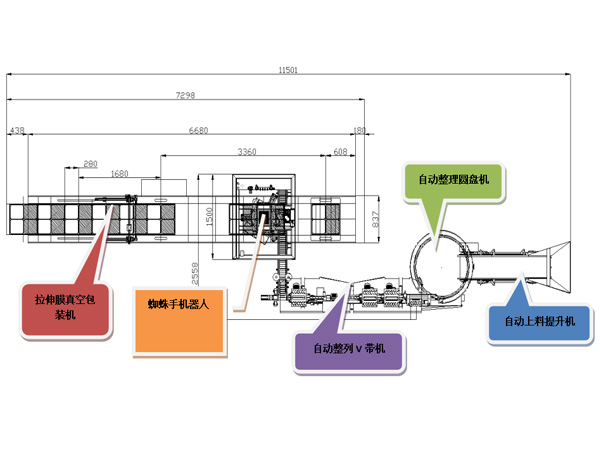

2. The equipment is mainly composed of 2 parts: ATFLS500 robot automatic feeder, AKLS stretch film vacuum packaging machine;

2.1. Automatic sorting disc machine: The main function is to arrange the messy sausages sent from the front end into a row and transport them to the next part;

2.2. Automatic alignment V-belt machine: connect the sausages sorted out at the front end, and convey the sausages through the three-segment V-shaped design belt, and each section of the conveyor belt is controlled by PLC, using electric eye detection to control the running speed of each section of the belt, so as to achieve the sausage conveying Continuity and stability; At the same time, there is a screening section in this part, which is used to remove too long, too short, and even-rooted sausages to ensure that the sausages entering the packaging area are qualified products;

2.3. Spider-hand robot: After sorting the sausage inside the host by grabbing and placing, the robot grabs and places the sausage in the designated area according to product specifications;

2.4. Stretch film vacuum packaging machine: this part is the main machine of the whole line, which consists of upper and lower film placement, film forming, upper and lower film sealing, coding system, cross cutting system, slitting system, scrap collection system, power system, finished product output, etc. Composition to realize the final process of automatic vacuum packaging.

technical parameter:

Hoist power: 0.25KW; disc machine power: 2.1KW; V-belt machine: 3.0KW; manipulator: 3.0KW; mechanical handpiece part: 1.5KW; stretch film vacuum packaging machine part: 12kw (different models have different power Different); total power of the whole line: about 22KW.

Power supply: 380V+N+PE;

Electrical appliances: Japanese brand low-voltage electrical, Inovance motion controller, etc.;

Motor: Inovance bus servo;

Vacuum pump: Pushu;

Vacuum processor: PIAB

Fan: Dragon Valley (Taiwan, China)

Maximum speed of disc finishing: 600 pcs/min;

Maximum speed of manipulator: 35 beats/minute;

Maximum speed of stretch film vacuum packaging machine: 3-5 steps/min

Overall dimensions of the whole line: (LxWxH): 11500*2558*2800mm (this parameter is equipped with a 560 stretch film machine); the length of the length can be shortened by moving the position of the hoist;

Motors, reducers, vacuum pumps, and electrical components are all domestic and foreign famous brand products with high stability

The whole wire frame body is made of SUS304 material;

Whole machine weight: 4000kg;

Tel: 86-757-86403516

Tel: 86-757-86403516 Tel: 15627782899

Tel: 15627782899 Fax: 0757-86407516

Fax: 0757-86407516 Email: info@fsaokai.com

Email: info@fsaokai.com Add: On the 3rd, Xingwang Road, Luocun,Nanhai,Foshan,Guangdong Province,China

Add: On the 3rd, Xingwang Road, Luocun,Nanhai,Foshan,Guangdong Province,China